Composites Bladder Inflation Molding Support

"Manufacture complex hollow FRP

composite structures with confidence"

CSS has more than 35 years of experience supporting the design and manufacture of complex hollow FRP composite structures produced with Bladder Inflation Molding (BIM).

Common Examples BIM Parts

- Tapered or Curved Tubular Structures

- Irregular Shaped Hollow Geometries

- Hollow Hubs or Joints

- Large Open or Closed Cylinders

- Hollow Ring Shaped Structures

- Hybrid Structures (Hollow & Solid Regions)

CSS helps Clients design and manufacture prepreg and resin infused bladder molded products. Our services include custom bladder design, tooling design, and BIM tailored product design and process development support.

Note: CSS does NOT manufacture or sell bladders ... but we do support development of in-house bladder fabrication capability.

Client support for in-house bladder molding production is provided through CSS' Composite Manufacturing Support services or, in the case of higher production volumes, CSS' Composites Overseas Sourcing Assistance.

Bladder Inflation Molding Advantages

- Facilitates fabrication of complex hollow composite structures

- Suitable for high volume production of small to medium size parts

- Yields excellent OML surface quality parts

Prepreg Versus Resin Infused Preforms

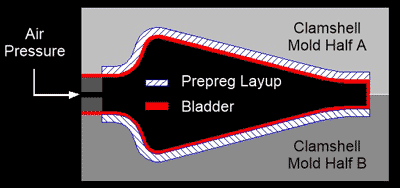

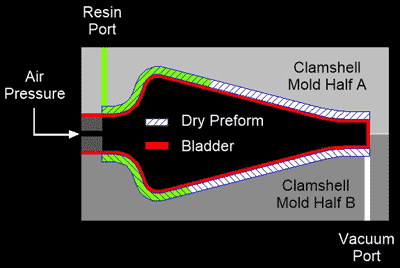

BIM parts may be fabricated from hot melt prepreg preforms or dry fiber preforms infused with resin during the bladder molding process. The bladder's role and bladder inflation pressure differ depending on the preform type.

In the case of prepreg bladders, the bladder's role is to consolidate the prepreg layers and maintain the consolidated part shape until the resin matrix cures. Higher internal bladder pressures are typically employed to generate resin flow, drive entrapped air out of the layup, and consolidate the fiber reinforced prepreg layers against the tool surface.

Prepreg Bladder Inflation Molding

A resin infusion bladder, on the other hand, is typically inflated with less pressure to avoid collapsing the dry fiber preform and shutting off essential resin flow channels. The resin infusion bladder's role is that of a soft tool surface during impregnation and to maintain wetted preform shape as the resin gels/cures.

Resin Infusion Bladder Inflation Molding

Bladder material selection is driven by part geometry, processing temperature, reusability requirements, and cost. Common bladder materials include latex rubber, polyamides (nylon), silicone rubber, and polyetheretherketone (PEEK).